Medical

Surface treatment for medical technology

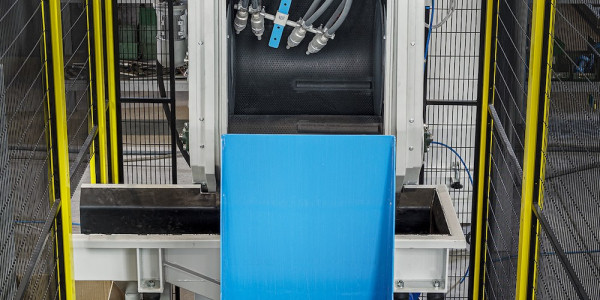

In the medical sector, the requirements are technologically the most stringent and difficult to meet. Prostheses, orthoses, implants and medical equipment must meet high standards. Implants are needed that require precise positioning of the workpiece in addition to the quality of the surface finish to be achieved. Turbotecnica has long offered automatic systems that save customers from having to perform surface treatment operations manually, greatly reducing operating costs and always guaranteeing uniform and consistent quality standards.

With both our compressed air and turbine systems, we guarantee the absolute quality required in a simple and reliable manner. The systems we offer are mainly customised to customer requirements and fully digitised. Applications not only for the orthopaedic sector, but also for all tools (scalpels, burs, rotary heads) that are used in the medical sector.

Air and wheel blast systems are often used to matt and roughen the surfaces of equipment and tools in the medical field, eliminating the shiny effect that is not recommended in the operating room due to reflection issues. Another topic is shot peening, which is indicated for ensuring greater mechanical resistance to titanium parts such as screws and pins for the orthopaedic sector.

During its 40 years of experience in the surface treatment sector, Turbotecnica has perfected shot blasting and shot peening systems in the medical field, facing challenges that have enabled to achieve a very high level of know-how while meeting the strictest standards in the industry.