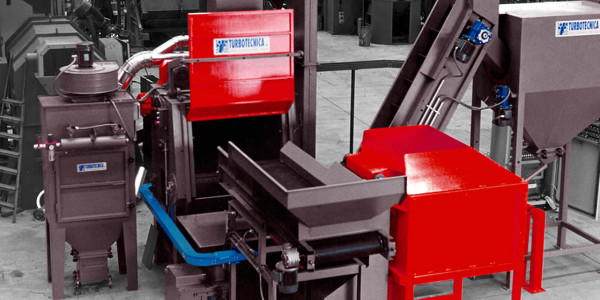

Tumble belt blast machines

Rubber (TB-G), steel (TB-A) and continuous flow (GTFC) blasting systems. The main advantages of a conveyor system are the complete exposure of all surfaces to the blast stream resulting in optimal surface processing performance.

They can be used for a wide range of materials, metallic and non-metallic.

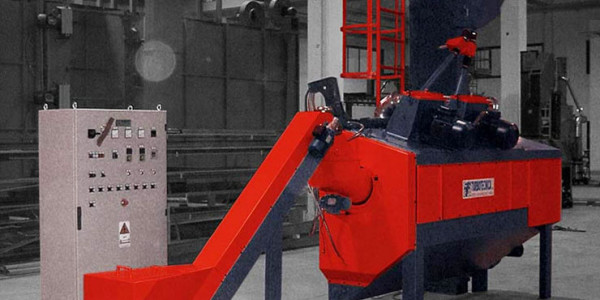

Rotary drum machines allow gentle and intensive blasting. Compact design, reliable and with high cleaning performance, they are solutions for desanding castings and descaling forged or heat-treated parts.

The loading of the parts can be done manually or automatically by means of a tilter, which gradually and gently pours the parts into the blast chamber. Similarly, unloading onto a Vibrating Conveyor can take place.

Our blasting systems guarantee high performance without the risk of damaging the parts to be processed. Depending on the application, we can opt for the Rubber or Steel Belt solution.

Another Chapter instead is the GTFC type machines which, thanks to the double combined movement of advancement and rolling of the pieces to be processed, prove to be an extremely automatic system for those who want to minimise the cost per piece.

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.