TRV

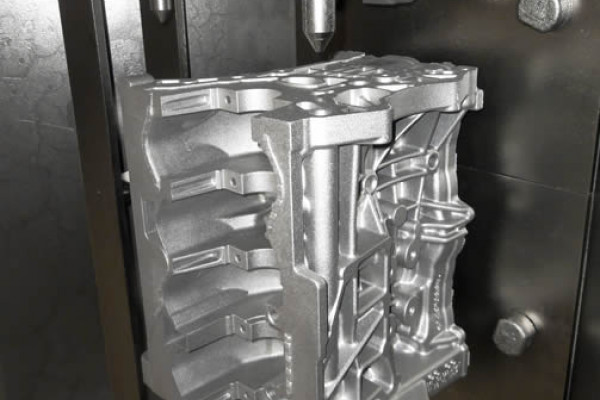

Optimum machining of parts with a particular shape

Each compartment is equipped with a swivel hook to accommodate stands on which to place the parts to be cleaned. The unloading area of the machine is open, which facilitates loading and unloading while parts are being sandblasted in the other compartments.

Each time the chamber rotates to its next position, the flow of abrasive from the turbines is interrupted until the table stops rotating. The continuously rotating hook ensures total coverage of the part, avoiding shadow areas that cannot be reached by the abrasive jet.

Technical details

Paint stripping, reconditioning, preparation for painting metal parts.

Magnetic separators (for desanding operations), turbine speed variator, idle or motorised satellites, special filter with fire prevention system.

Sectors of employment:

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.