ALFA

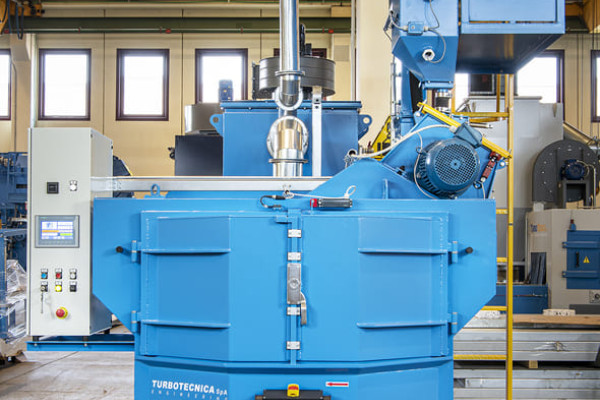

Blasting system with self-cleaning filter

Technological efficiency for surface cleaning

Installed directly on the floor without additional masonry work, ALFA spinner hangar blast machines are the simplest, most versatile and economical solution to surface processing problems.

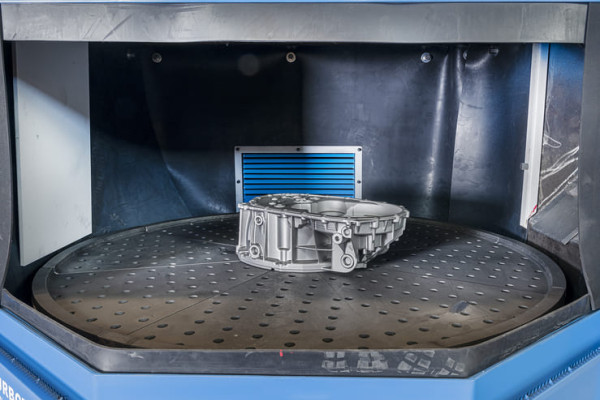

The material is placed on the table which, as it rotates, allows the upper and side surfaces to be subjected to the effect of the grit projected by the turbines.

The ALFA blast system supports a table diameter of 500 to 2500 mm, with a load capacity of up to 2000 kg.

Technical details

Cleaning of dies, forged, cast, moulded, welded and brazed materials.

Magnetic separators (for desanding operations), turbine speed variator, idle or motorised satellites, special filter with fire prevention system.

| Machine Type | Table ⌀ in MM | Opening Height in MM | Loading Capacity in Kg | Turbines Quantity | Turbine Power in kW | Turbine Diameter in MM | Dimensions in MM | ||

|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||||

| ALFA 10 | 1.000 | 400 | 500 | 1 | 5,5 | 260 | 1.500 | 1.250 | 2.800 |

| ALFA 14 | 1.400 | 500 | 500 | 1 | 7,5 | 360 | 1.650 | 1.250 | 3.200 |

| ALFA 18 | 1.800 | 450 | 1.000 | 2 | 7,5 | 360 | 1.800 | 1.650 | 3.200 |

| ALFA 20 | 2.000 | 500 | 1.500 | 2 | 7,5 - 11 | 360 | 2.000 | 1.850 | 3.400 |

| ALFA 23 | 2.300 | 600 | 2.000 | 2 | 7,5 - 11 | 360 | 2.400 | 2.200 | 3.800 |

| ALFA 25 | 2.500 | 1.000 | 2.500 | 3 | 7,5 - 11 | 360 | |||

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.