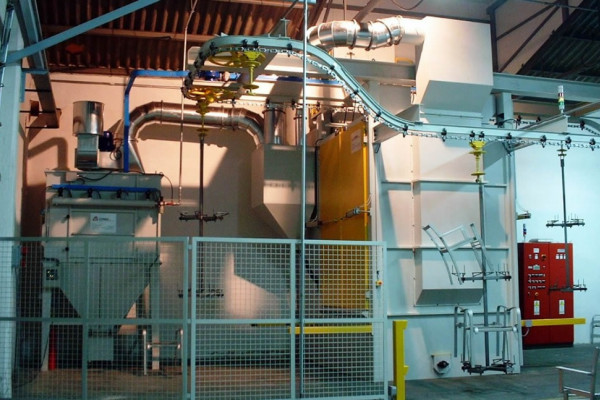

Deltamatic - overhead conveyor blast machines

Deltamatic blast machine: maximum performance for cleaning and deburring

Guarantees high productivity for cleaning and deburring cast, moulded, forged and heat-treated parts

The Deltamatic blast system is equipped with an overhead conveyor, designed to achieve high performance from continuous operation of the turbines. The materials are hung on a number of hooks moved by an overhead conveyor of monorail or bi-rail type or with hoists.

Inside the Deltamatic overhead conveyor blast machine, the hook is made to rotate around its own axis and translate in front of the turbines (mounted on one side of the chamber): the result is uniform processing of the surfaces within the space available.

The customer can choose the size of the blasting equipment and the loading capacity according to the materials intended to blast.

Technical details

Inverters on the turbines

Automatic grit dosing dampers

Automatic grit refill

Soundproof boxes

Magnetic Separators

Absolute Filters

Atex Components

Automatic loading and unloading

systems

Preparation for the painting of metal parts

Paint stripping, reconditioning

Cleaning

Corrosion removal

Machining deburring

Moulding deburring

Preparation for gluing

Calamine removal

Aesthetic blasting

| Machine type | Loading dimensions in mm | Loading capacity in Kg | Turbines quantity | Turbine power in kW | Turbine diameter in mm | |

|---|---|---|---|---|---|---|

| Diameter | Height | |||||

| Deltamatic 250 GR 7-15 | 700 | 1.500 | 250 | 2 | 4 - 5,5 | 260 |

| Deltamatic 500 GR 10-15 | 1.000 | 1.500 | 500 | 2 | 7,5 - 11 - 15 | 360 |

| Deltamatic 500 GR 15-20 | 1.500 | 2.000 | 500 | 3 | 7,5 - 11 - 15 | 360 |

| Deltamatic 500 GR 15-25 | 1.500 | 2.500 | 500 | 3 | 7,5 - 11 - 15 | 360 |

| Deltamatic 500 GR 17-22 | 1.700 | 2.200 | 500 | 3 | 7,5 - 11 - 15 | 360 |

| Deltamatic 1000 GR 20-20 | 2.000 | 2.000 | 1.000 | 4 | 7,5 - 11 - 15 | 360 |

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.