DELTA - overhead conveyor blast machines

Blasting system with self-cleaning filter

Versatile, flexible, suitable for any use

The overhead conveyor blast machine developed by Turbotecnica is a very flexible and versatile machine.

It is suitable for multiple uses. It allows you to optimise workflows for surface processing, reconditioning and preparation for painting of any surface, always guaranteeing optimum workpiece cleanliness, even for those with more complex shapes.

The models differ in load capacity, chamber volume and productivity. The models can be customised according to customer requirements. The solution offers the possibility of batch processing with single, double or multiple hooks. This type of machine offers the great advantage of being able to load and unload in parallel, thus optimising time and costs.

Overhead conveyor blast machines can be installed directly on the floor without any prior masonry work and are equipped with a self-cleaning filter.

Technical details

Inverters on the turbines

Automatic grit dosing dampers

Automatic grit refill

Soundproof boxes

Magnetic Separators

Absolute Filters

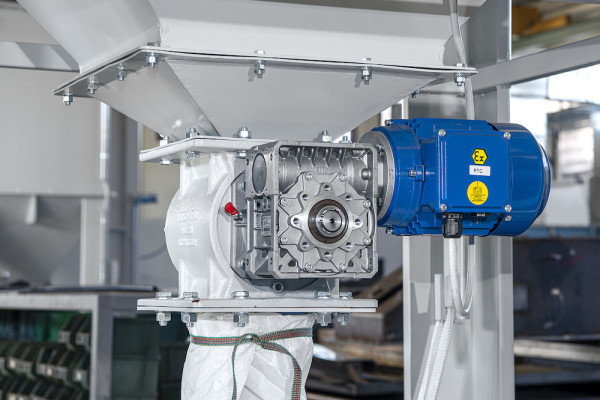

Atex Components

Automatic loading and unloading systems

Preparation for the painting of metal parts

Paint stripping, reconditioning

Cleaning

Corrosion removal

Machining deburring

Moulding deburring

Preparation for gluing

Calamine removal

Aesthetic blasting

Sectors of employment:

| Machine type | Loading dimensions in mm | Loading capacity in Kg | Turbines quantity | Turbine power in kW | Turbine diameter in mm | |

|---|---|---|---|---|---|---|

| Diameter | Height | |||||

| Delta 100 GR 5-10 | 550 | 1000 | 100 | 2 | 4 - 5,5 | 260 |

| Delta 250 GR 7-10 | 750 | 1000 | 250 | 2 | 4 - 5,5 | 260 |

| Delta 250 GR 7-15 | 750 | 1500 | 250 | 2 | 4 - 5,5 | 260 |

| Delta 500 GR 10-15 | 1000 | 1500 | 500 | 2 | 7,5 - 11 - 15 | 360 |

| Delta 500 GR 15-20 | 1500 | 2000 | 500 | 3 | 7,5 - 11 - 15 | 360 |

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.