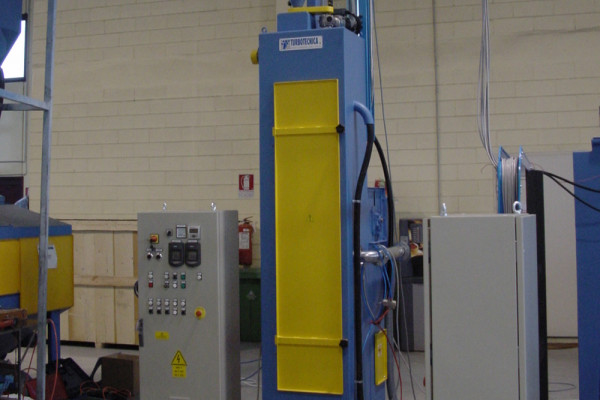

TB AC - compressed air sandblasting machine

Systems for processing non-conventional materials

Turbotecnica implements various customised solutions depending on the material to be processed and the required finish. These include the TB AC rubber belt system for processing bulk parts, continuously operating rotary tables, tables with satellites, pass-through belt systems, and sandblasting machines for inside pipes or cylinders.

Each machine is equipped with a compressed air sandblasting machine operating under pressure or under vacuum, a grit recycling system, a variable number of sandblasting nozzles, a grit supply silo, and a self-cleaning cartridge-type dry filter. Floor installation with no masonry work.

Technical details

Deburring, cleaning, surface preparation for subsequent coatings, roughening, shot peening on all types of metal and non-metal parts.

Magnetic separators (for desanding operations), turbine speed variator, overhead conveyor with Y or closed-loop configuration, digital control panel, special filter with fire prevention system.

Find out more about our machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.